Poly bags

Stay compliant

With new sustainability rules and anti-plastic regulations coming into play, remaining compliant with your poly bags is essential. This is where we come in. We’ll audit and advise you on the best choices, whilst always keeping sustainability front of mind.

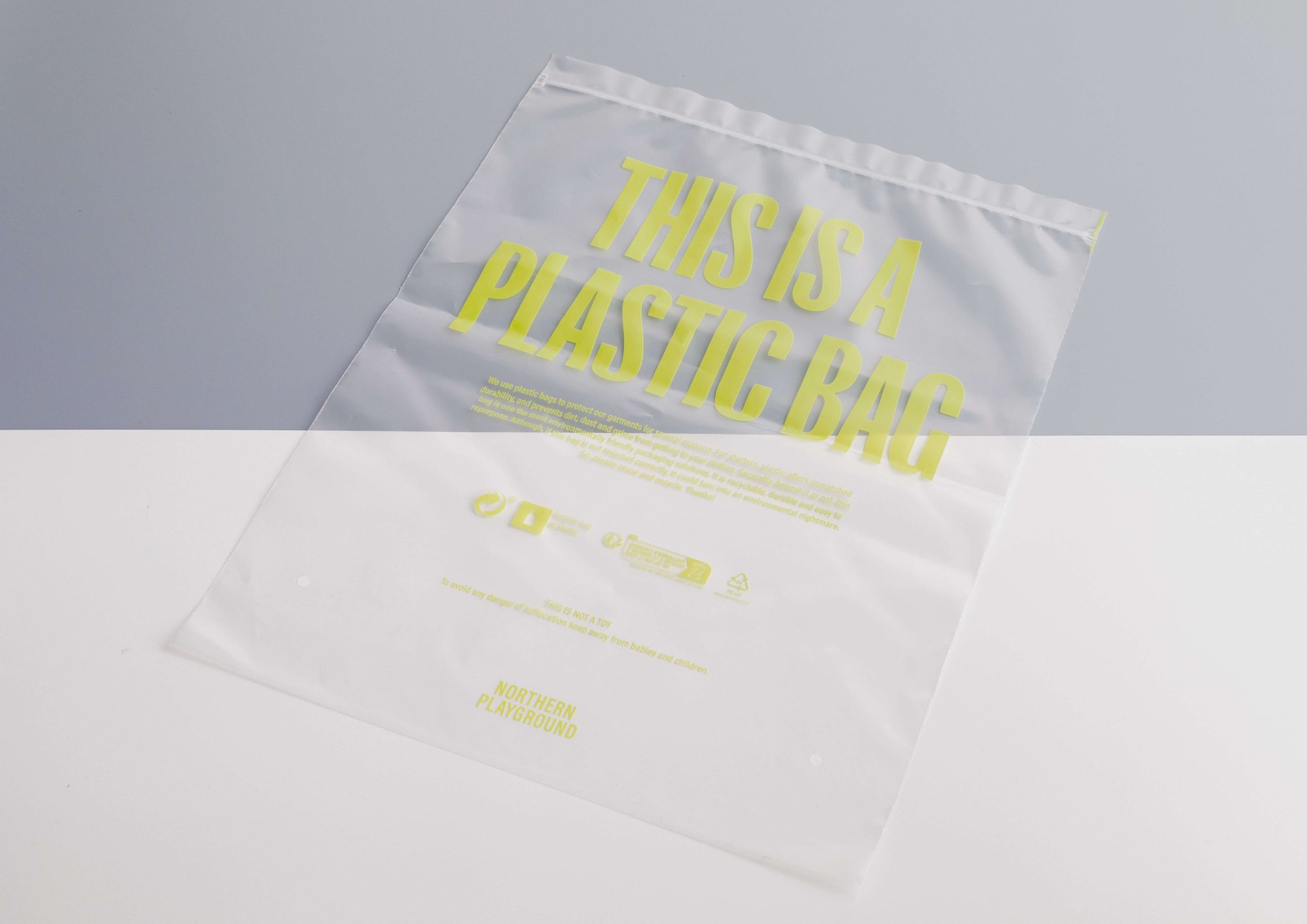

Don’t sacrifice sustainability

Gone are the days when single-use, unsustainable plastics were the only option. We offer a range of eco-friendly poly bag materials from completely plastic-free options and water-soluble plastics to recyclable and recycled options.

Certified materials

Recycled LDPE

- Sourced from pre-consumer plastic waste

- Recyclable

- GRS certified

Cornstarch

- Biodegradable plastic made from plants

- Recyclable

- EN 13432 compliant OK compost certified

Green PE

- Bio-based material made from sugarcane waste

- Recyclable

- Certified carbon neutral by The Carbon Trust

Recycled HDPE

- Sourced from pre-consumer plastic waste

- Frosted for a luxurious feel

- GRS-certified plastic recyclable in most household waste collections

Water soluble

- Dissolvable in hot water

- Marine safe

- Non-toxic

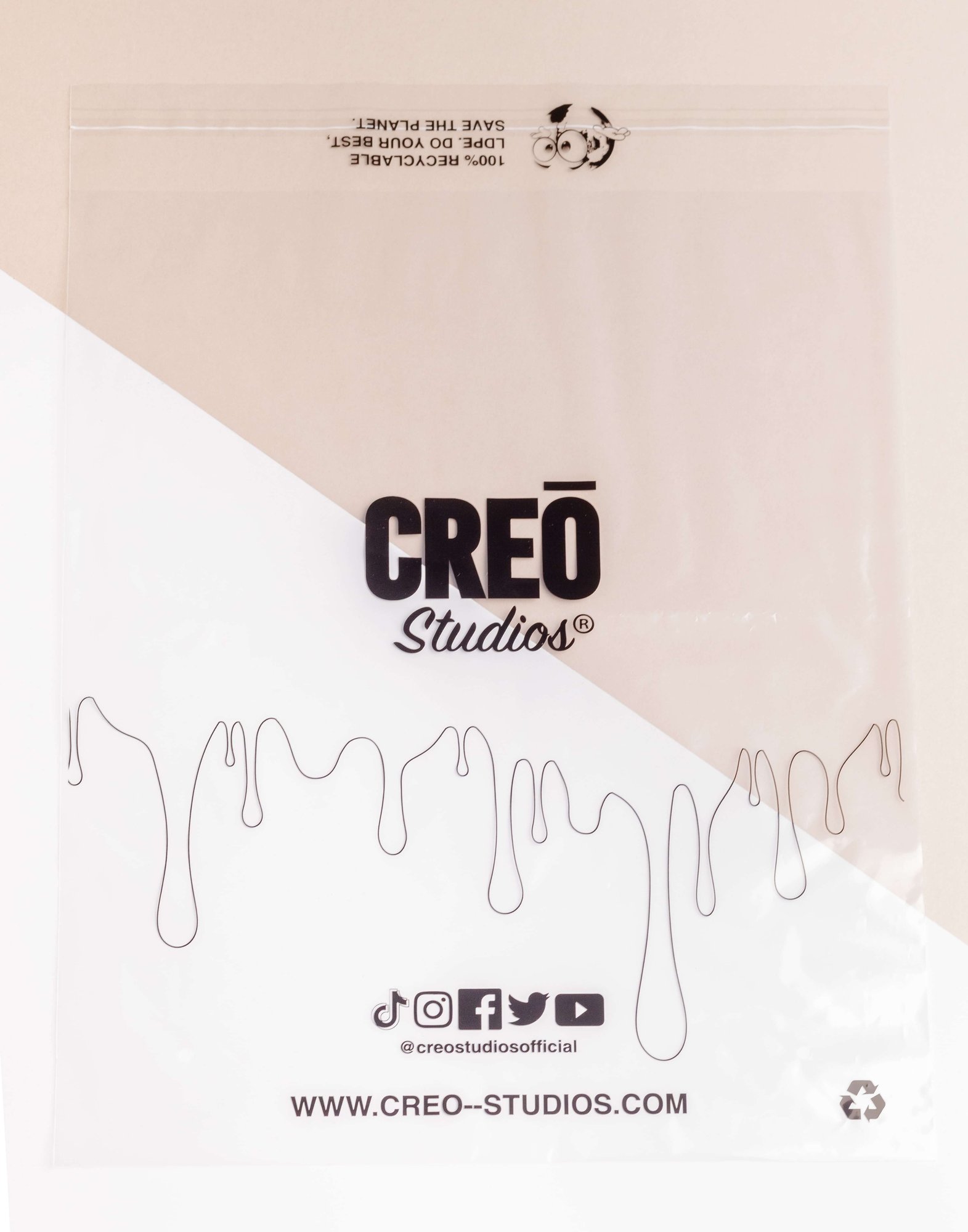

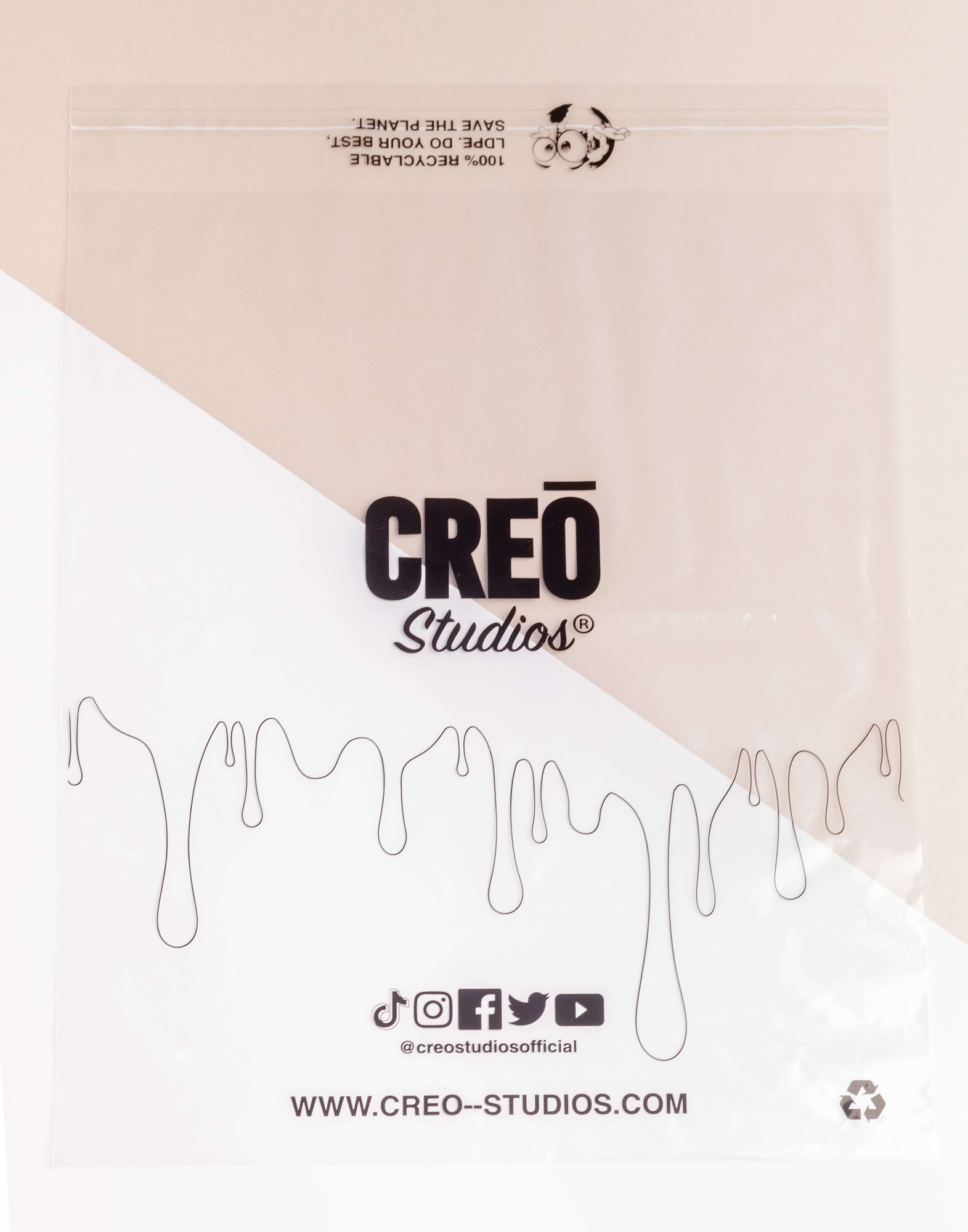

Keep your garments protected and on-brand. Speak to us about custom garment bags.

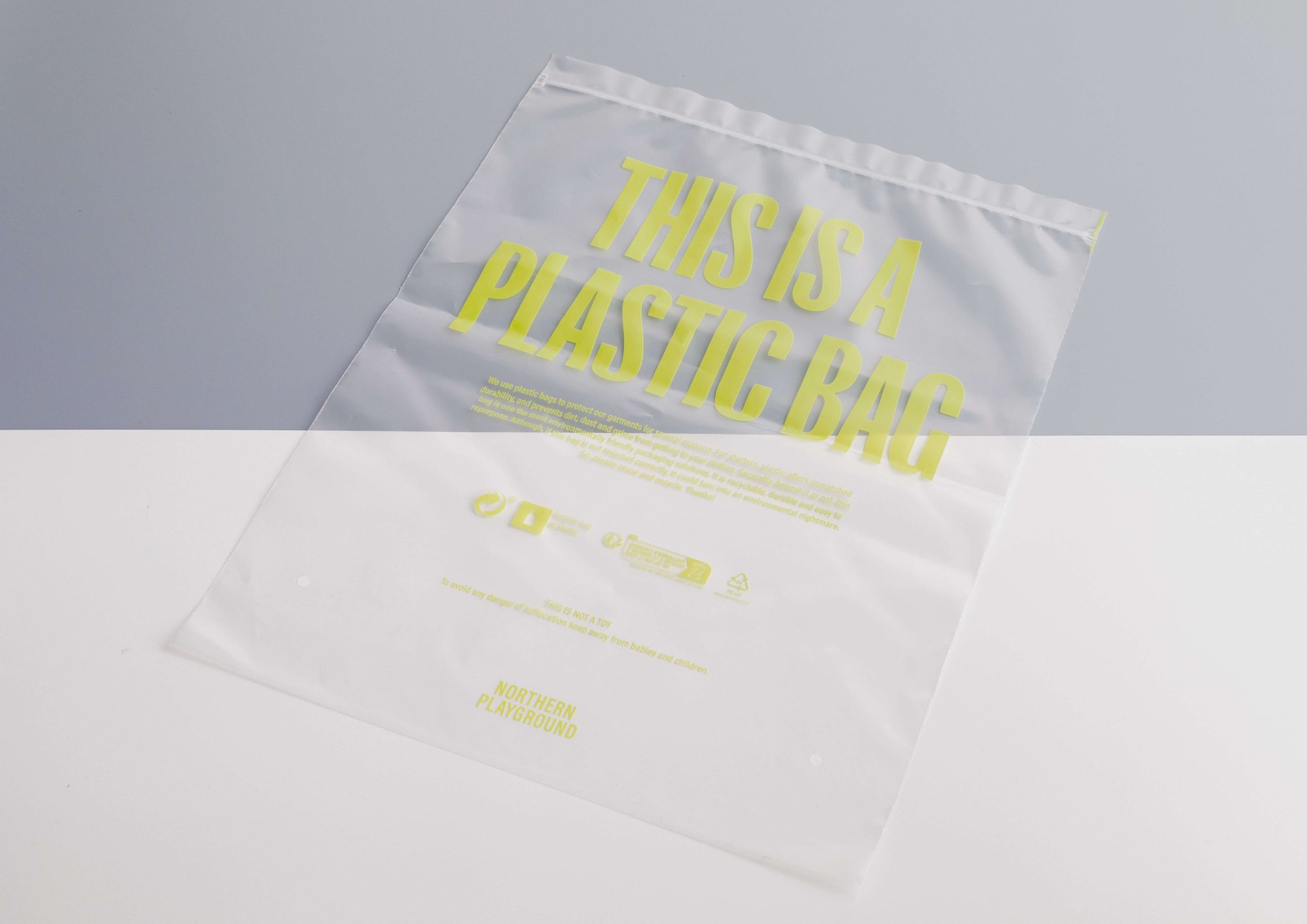

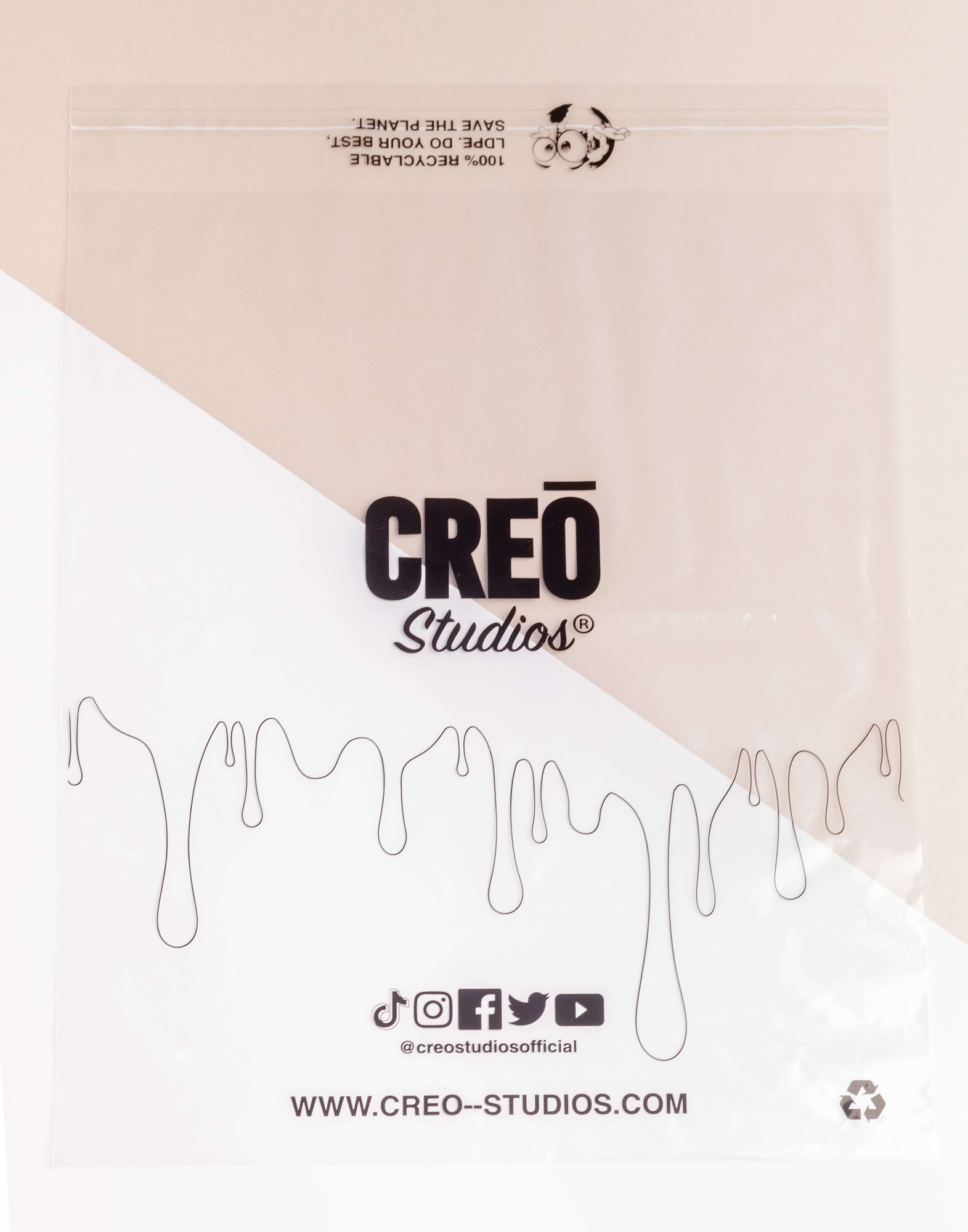

Customer favourites

Our poly bags are available in various shapes, sizes and materials to meet your needs. Here are some of our most popular products to inspire you.

Customer favourites

Spruce: A plastic-free alternative

Want to go completely plastic-free? Our Spruce bags are the answer. Made from translucent glassine paper, Spruce bags are an alternative option to plastic made using pulp sourced from FSC-certified forests. With all the qualities of a plastic poly bag, it’s a sustainable alternative that you can rely on.

Poly bags in the supply chain

Whatever your product, it needs to travel through the supply chain in pristine condition. This could be from the manufacturing location to the distribution centre or to the consumer. After all, damaged goods increase returns and lost revenue, as well as having a negative impact on the environment. This is why poly bags are an essential.Download your poly bag Lookbook

Truly sustainable sourcing

A large portion of carbon emissions comes from the logistics in the supply chain. Our sustainable stitch-to-store sourcing model aims to minimise this impact.

With global distribution centres, we can ship your chosen labels directly to your vendor from the facility that’s closest to the destination. We’ll also handle all the stock management, so you have less to deal with.

Why choose Weavabel?

Minimum stock value

Our minimum stockholding value is £10,000 annually. This can be set up across multiple currencies and for several locations.

Fast delivery

A quick turnaround of your stock, with lead times typically taking between two and four weeks.

Hassle-free orders

Simple repeat ordering through our stockholding site, making your products easily accessible.

Great communication

We’ll liaise all the finer details directly with your vendors, giving you one less thing to manage.

Webinar: Which poly bag is right for my brand?

Watch our latest webinar where we discuss different poly bag qualities as well as the latest innovative materials that promote sustainability.

Download our guide to poly bags

Frequently asked questions

What certifications do you offer?

We have a range of certified materials, including FSC, GOTS, GRS, Carbon Neutral and more. You can find out more about our certifications here.

What inks do you use for printing?

We predominantly use vegetable and soy-based inks rather than chemical-based inks. This may vary, so always discuss with your point of contact.

What production locations can you produce poly bags in?

India, the EU, China, Hong Kong and the UK.

What type of poly bag is best for my brand?

With so many sizes, styles and material options, it can be overwhelming to decide which will work best for you. Get in touch with us today and our experts can guide you.

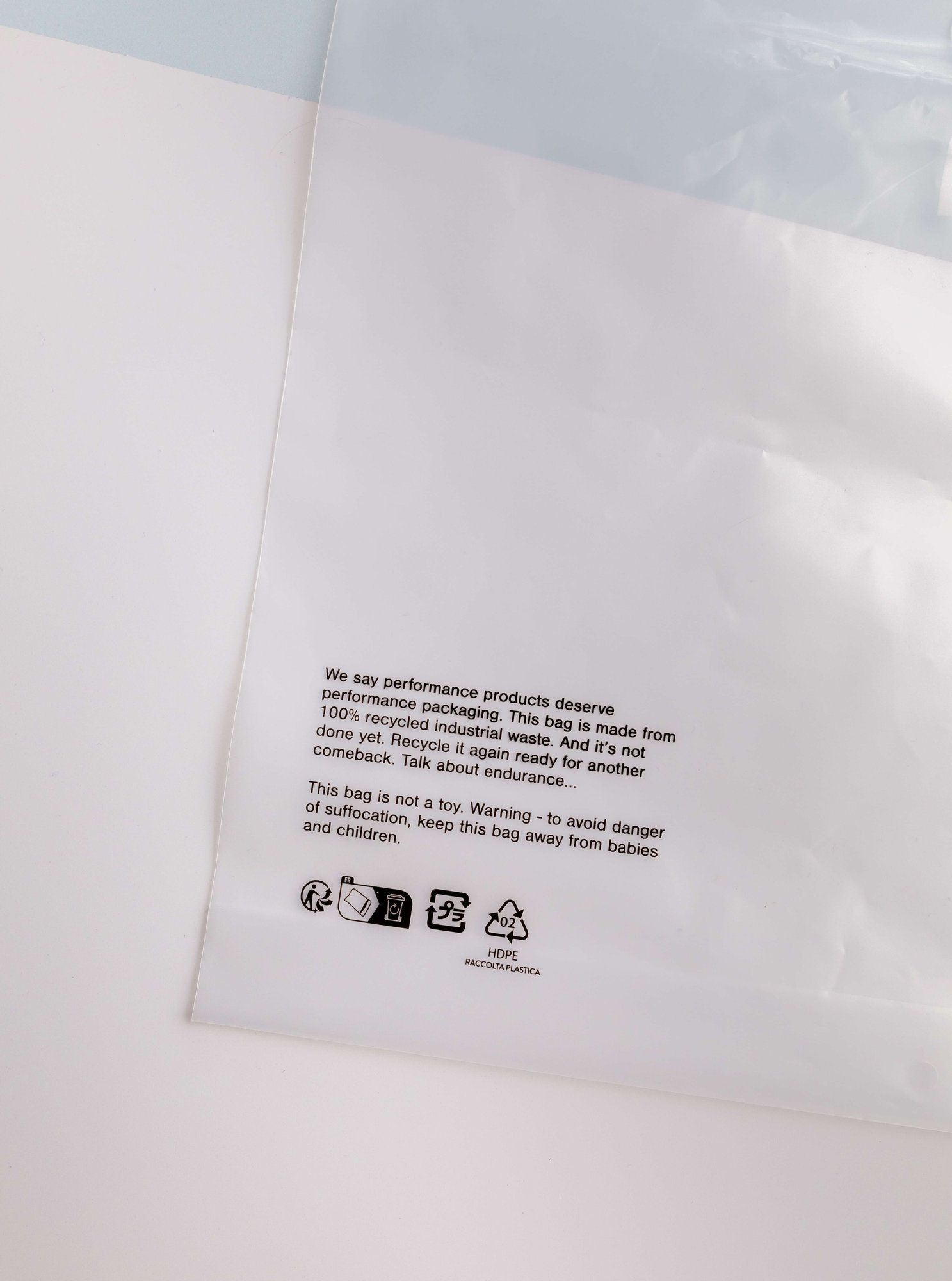

What are the important logos and signs to look out for when choosing a polybag?

Mobius loop- Product is capable of being recycled but not necessarily accepted in all recycling collection systems.

Triman - Product can be recycled through household waste disposal sorting.

Standard EN - Products certified to be industrially compostable according to the European standard EN 13432/14955.

Resin codes - There are seven codes that identify the type of plastic resin used to make a product. They feature a ‘chasing arrows’ symbol with the ‘Resin Identification Code’ between one and seven.

PET - Polyethylene Terephthalate

HDPE - High-Density Polyethylene

PVC - Polyvinyl Chloride

LDPE - Low-Density Polyethylene

PP – Polypropylene

PS – Polystyrene

Miscellaneous - Polycarbonate, BPA and other plastics

CPE - Chlorinated polyethylene

AEVA - Ethylene Vinyl Acetate

What does all the terminology mean?

Biodegradable

Biodegradable plastics can be decomposed by living organisms — usually microbes — into water, carbon dioxide and biomass. These plastics are commonly produced with renewable raw materials, microorganisms, petrochemicals or a combination of all three.

Recycled and Recyclable

Plastics can be recycled through mechanical or chemical recycling. Mechanical recycling involves plastic being washed, ground and melted. Chemical recycling breaks plastic down into monomers to form new polymers that can be reused.

Compostable

Compostable plastics are derived from renewable materials such as corn, potato and tapioca starches, as well as cellulose, soy, protein and lactic acid. Compostable plastics and non-toxic and decompose into carbon dioxide, water and biomass.

Water soluble

This polymer is inherently biodegradable. Biodegradation has been observed by at least 20 different generaof bacteria and several yeasts and moulds which occur in activated sludge, compost, facultative ponds, landfills, anaerobic digesters and septic systems and in natural soil and aquatic environments. Sturm (aquatic) biodegradation tests show that the formulations degrade in the presence of activated sewage sludge at a similar rate to cellulose.

Sign up for our newsletter

Want to keep up to date with industry developments, trends, product launches and more? Sign up to our newsletter to get the latest delivered to your inbox.